What More UK, the Lancashire housewares manufacturer, and owner of the well-known brand Wham, pride themselves on constantly innovating to suit market needs. They have a great capacity for innovation thanks to their tooling team being completely in house, which gives the ultimate flexibility for creating new to market products.

This year’s huge development is bakeware designed to fit in air fryers. Over 30% of households just in the UK now own an air fryer, and the market is expected to show a volume growth of 8.9% in 2024, making it the ideal time to launch. They come in a Pewter finish, with Skandia extreme non-stick coating.

Air fryers can cook pretty much anything you can bake in a regular oven – but quicker and tastier. The current problem is anything that’s liquid based – whether this is eggs, lasagne, cakes, pies with fillings – liner type products tend to slow the cooking process and aren’t practical for removal. This is where the new Air Fry range from Wham comes in.

The products include a small loaf tin, and an oval tin designed to make lasagne or pies in, amongst other innovative solutions. A deep pudding dish is available for those glorious sticky toffee puddings, and mini fluted round dishes for delicious quiches. They’re fully non-stick, which helps the end result to come out perfectly. Now your favourite kitchen gadget can cook all your favourite recipes!

What More UK Director Tony Grimshaw OBE is very proud of their new inventions. He said,

“Air fryers are here to stay, and getting ever more popular. We saw the absolute need in the market for smaller bakeware that can be used to make things that really couldn’t be made in the air fryer before, such as lasagne.”

“The range has been exhibited at our major global trade shows, including Ambiente in Frankfurt and The Inspired Home Show in Chicago. Buyers were really impressed with our innovative solution, and the fact they were to our usual highest quality and as always proudly Made in Britain. I’m sure they’ll be flying off the shelves very soon too!”

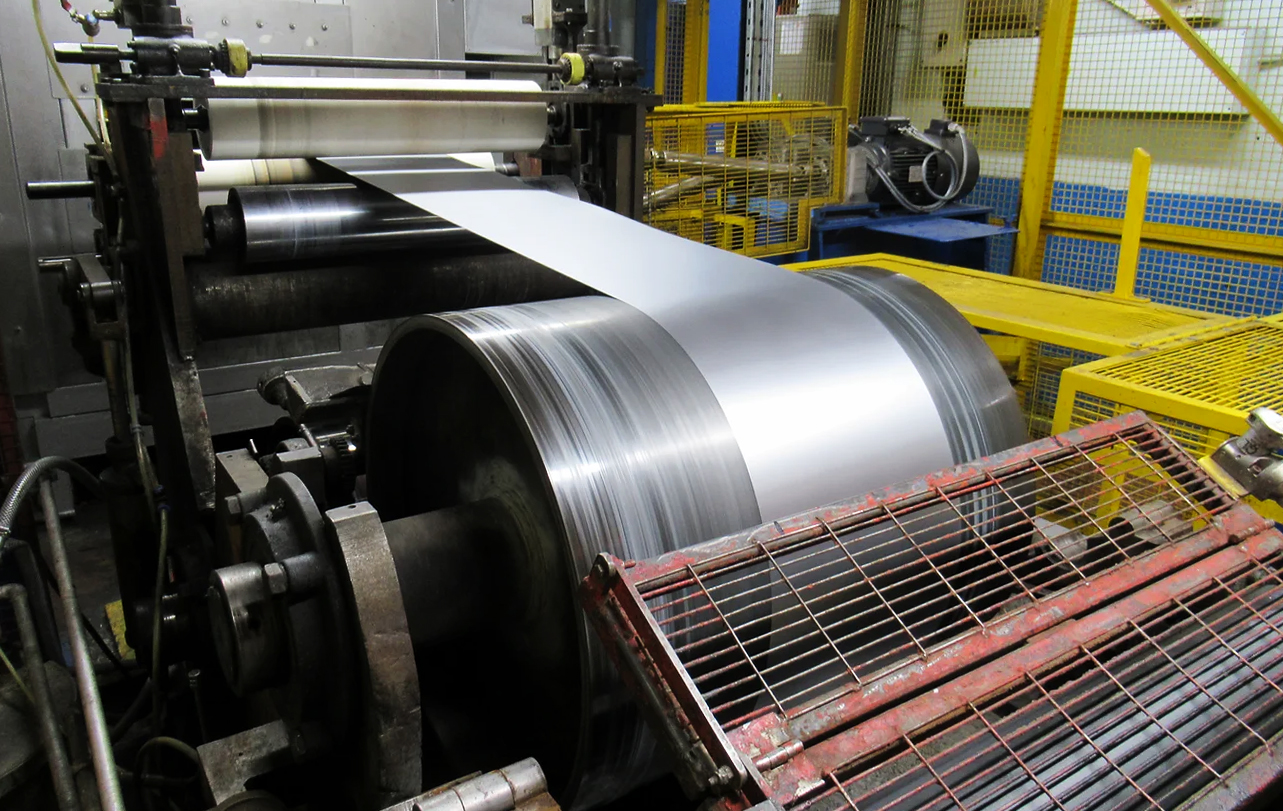

What More UK manufacture metal and plastic housewares of all kinds, from around the sink items to garden, garage and officewares. What More is a proud member of Made in Britain and they export UK branded goods to 75 countries around the world, in addition to every major UK supermarket and another 1600 independent retailers.

For more information about What More UK visit www.whatmoreuk.com

PushPan® has been a great investment for What More, and we’ve worked hard on new tooling to expand the range. We are excited to return to Ambiente and Chicago, the two biggest global trade shows for our industry, and we can’t wait to see old friends and new and continue our export growth.

PushPan® has been a great investment for What More, and we’ve worked hard on new tooling to expand the range. We are excited to return to Ambiente and Chicago, the two biggest global trade shows for our industry, and we can’t wait to see old friends and new and continue our export growth.